Newark Wire News

Newark Wire News

A Guide to Different Types of Wire Mesh Weaves

Weaving is everything when it comes to stainless and industrial wire cloth with woven wire mesh and wire mesh panels. The weave is what determines how the wire cloth can be used and in what capacity. With that in mind, here is a list of the types of weaves to choose from when purchasing wire cloth-related products.

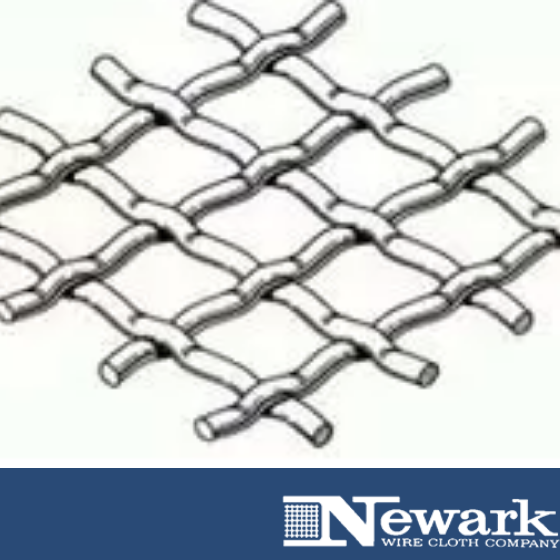

Pre-Crimp Weaves

First, let’s take a look at the pre-crimp weaves. These weaves are typically used for wire and space cloth that is more on the coarse side. The following is an overview of the three different types:

- Pre-Crimp – Generally speaking, to add strength and rigidity to the wire cloth, pre-crimp weaves are crimped (or folded so the wires have small folds or ridges) before they are weaved. This makes it possible for the warp and shute wires to rest securely and prevent them from unnecessary movement.

- Lock Crimp – Another type of pre-crimp weave is the lock crimp. This type of weave uses the grooves left from the crimping process to literally lock the weaves together at the point in which they intersect. This makes the wires sturdier and further prevents movement.

- Inter-Crimp or Multiple Crimp – Lastly, the inter-crimp or multiple crimps offers yet another enhancement on the basic crimp weave. With this method, both the warp and shute wires are crimped with added crimps between the points of intersection. This technique is often needed when weaving larger openings with fine wires. The process ensures that the warp and shute are properly locked and also helps to add accuracy and rigidity.

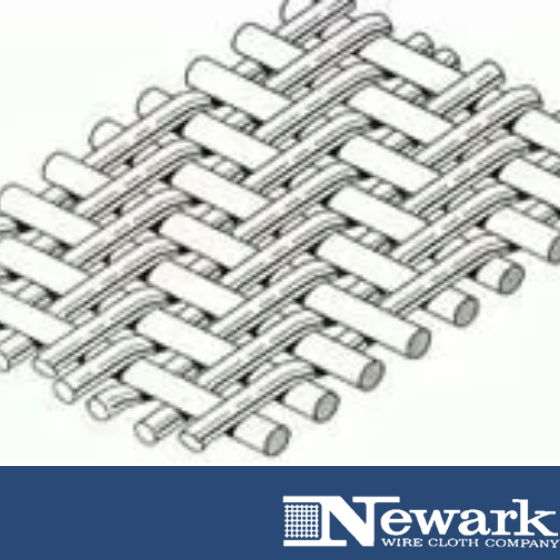

Plain Weaves

This is the most common type of weave used for wire cloths. In this case, there is no pre-crimping before the wires are weaved. Rather, the crimping of both the warp and shute is a result of the plain weave pattern requires that each shute wire must pass over and under successive rows of warp wires.

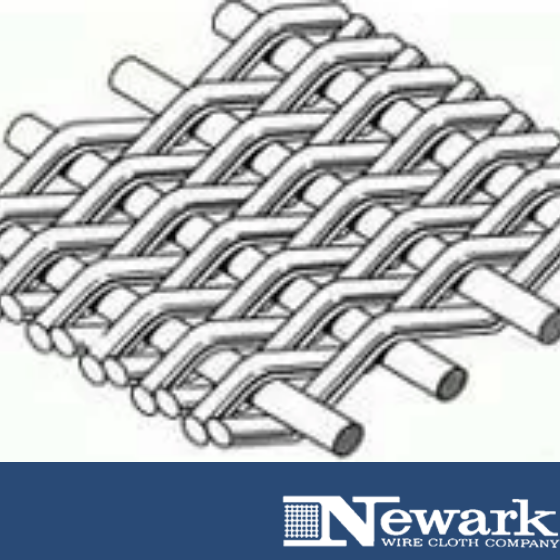

Filter Cloth

In terms of filter cloth, the types of weaves to be aware of are as follows:

- Plain Dutch Weave – This type of weave uses a similar technique as that of plain weaves. However, the warp wires have a larger diameter than the shute wires. The lighter shute brought closer together, which forms a dense filter. This weave appears to be wedge-shaped or tapered at the opening.

- Twill Dutch – This filter cloth includes a combination of twill and Dutch weave. This uses a technique in which the warp wires that are larger in diameter pass over and under the smaller shute wires. This caused the shute to be closer and results in a filter cloth that is tightly woven and with wedge-shaped or tapered openings.

- Twill Dutch Double – This is similar to the Dutch twill weave. However, due to wires sizes that are properly chosen, the shute wires overlap before they are driven into their tight positions. This makes for double wires in the shute direction per inch.

- Stranded – With this weave, both the shute and warp wires are made of separate wires, rather than single wires. This creates a twill pattern, which results in the mesh that is extremely strong and tight.

Twill Weave

Twill weave creates a wire cloth in which each shute and warp wire passes over and under the two adjacent wires successively; this occurs in both the shute and warp directions. This pattern makes it possible to weave heavier wires into various types of mesh.

Key Takeaways:

- When it comes to wire cloths, weaving is everything

- Pre-crimp weaves are used for wire and space cloths

- Plain weaves are most commonly used for wire cloths

Overall, when it comes to considering woven wire mesh sizes and the proper wire cloth, the type of weave is vital. No matter if you are seeking a balanced weave, dutch weave, or whatever type you prefer, we have products to suit your needs. If you need more help understanding the various types of weaves, contact our team of experts here at the Newark Wire Cloth today.