Test Sieve Certification & Re-Certification

Test Sieve Certification & Re-Certification

Be Certain Your Test Sieves Measure Up!

The latest revision of the ASTM E11 Specification is ASTM E11-20.

Test Sieves are digitally inspected.

- Measurement and statistical reporting of the measured apertures in test sieves are more precise; enhanced digital accuracy and imaging, apertures are measured with a computer aided digital optical video imaging system linked to custom statistical software.

- Measurement system is regularly calibrated to NIST traceable standards.

- Test Sieves can be supplied certified or re-certified to ASTM E11-20 or ISO 3310 Specifications.

- Certification and Re-Certification reporting is presented graphically as a Histogram.

- Each Test Sieve is identified with a serial number and NIST traceable documentation.

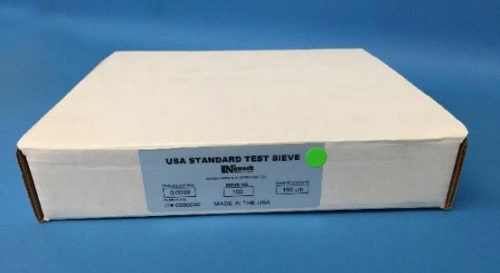

- Each Test Sieve is individually boxed.

Test Sieves can be supplied inspected to one of (3) different confidence levels.

Compliance Test Sieve (66% Confidence Level) – The Test Sieve is manufactured using sieve cloth that has been inspected and found to be in accordance with ASTM E11 (Table 1, Column 7 and factoring in the maximum standard deviation as shown in Column 8). The sieve cloth was measured prior to it being mounted in the sieve frame. Documentation includes a Certificate of Compliance

Inspection Test Sieve (99% Confidence Level) – The Test Sieve is manufactured using sieve cloth that was inspected after being mounted in the sieve frame. The sieve cloth meets the requirements of ASTM E11 (Table 1, Column 9 and factoring in the maximum standard deviation as shown in Column 10). Documentation includes a histogram stating at a minimum the value of the average opening sizes separately for both the warp and shute wires in the sieve cloth.

Calibration Test Sieve (99.73% Confidence Level) – The Test Sieve is manufactured using sieve cloth that was inspected after being mounted in the sieve frame. The sieve cloth meets the requirements of ASTM E11 (Table 1, Column 11 and factoring in the maximum standard deviation as shown in Column 12). Documentation includes a histogram stating the number of apertures and wire diameters measured, the average aperture size, standard deviation, and average wire diameter separately for both the warp and shute wires in the sieve cloth. At a minimum, at least twice as many apertures are measured for a Calibration Test Sieve certification as compared to an Inspection Test Sieve certification.

Inspection Test Sieve (99% Confidence Level) – The Test Sieve is manufactured using sieve cloth that was inspected after being mounted in the sieve frame. The sieve cloth meets the requirements of ASTM E11 (Table 1, Column 9 and factoring in the maximum standard deviation as shown in Column 10). Documentation includes a histogram stating at a minimum the value of the average opening sizes separately for both the warp and shute wires in the sieve cloth.

Calibration Test Sieve (99.73% Confidence Level) – The Test Sieve is manufactured using sieve cloth that was inspected after being mounted in the sieve frame. The sieve cloth meets the requirements of ASTM E11 (Table 1, Column 11 and factoring in the maximum standard deviation as shown in Column 12). Documentation includes a histogram stating the number of apertures and wire diameters measured, the average aperture size, standard deviation, and average wire diameter separately for both the warp and shute wires in the sieve cloth. At a minimum, at least twice as many apertures are measured for a Calibration Test Sieve certification as compared to an Inspection Test Sieve certification.

The documentation certificate for an Calibration Test Sieve includes (at a minimum) the number of openings and wire diameters measured, the average opening size and average wire diameter when measured in both the warp and shute direction of the sieve cloth, and the standard deviation.