When you invest in wire cloth or fabricated wire cloth parts for your project, you want assurance that the products are of the highest quality.

At Newark Wire Cloth, our products meet the following standards:

- ASTM International E2016, which sets industry standards for wire cloth, also known as industrial woven wire fabric, used for separating particles.

- ASTM International E11, which covers the design and construction of testing sieves made of wire cloth that are used to classify materials by particle size

- ASTM International aerospace material standards used to evaluate components, devices and materials used primarily by aircraft and aerospace industries

- ISO 9001, the international standards used to meet requirements for quality management systems. These standards ensure we consistently provide products and services that meet both regulatory and customer requirements.

- AS9100, which incorporates the ISO 9001 requirements and adds additional definitions, notes and requirements for the aviation, defense and space industries

Our employees work with these requirements and standards every day in manufacturing wire cloth products. Our raw materials must meet our quality levels, and our quality assurance inspection teams make sure that products adhere to all applicable regulations.

Whether your business requires corrosion-resistant materials, highly polished finishes, or precise measurements, our manufacturing, assembly, welding and brazing processes are designed to meet all your specifications.

The end result is that our customers in aerospace, automotive, food and beverage, medical and pharmaceutical industries trust in Newark Wire Cloth products. Our top quality work speaks for itself.

Newark’s commitment to quality woven wire mesh includes:

- Meeting or exceeding industry and government requirements

- Highly trained employees

- Processes designed to meet customer specifications

To learn more about available Newark Wire Cloth products and standards, contact us today.

Whether your needs involve a corrosion resistant metal, delicate scientific accuracy or the cleanliness of a polished finish for the food industry—Newark’s manufacturing, assembly, welding and brazing techniques are all designed to meet your quality requirements.

How To Order Wire Cloth

When ordering Newark Wire Cloth products, you may have questions about the type of wire cloth products to order. Below are some prompts to help you determine the right items for your manufacturing needs.

When ordering, please specify:

- Product Application. Conditions such as environment and temperature often play a key role in determining the material selection and type of wire cloth needed.

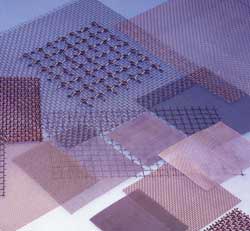

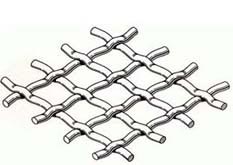

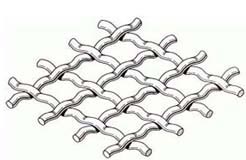

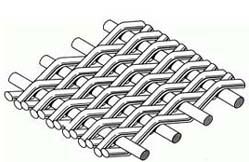

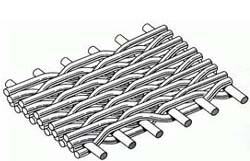

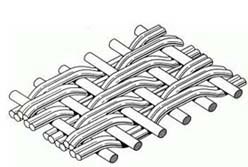

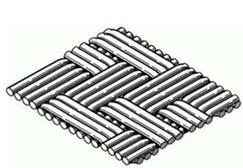

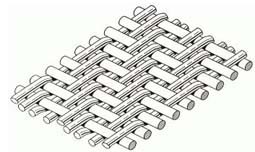

- Type Specifications. Knowing the right wire cloth mesh size helps us make sure you have the right wire cloth screen or wire cloth baskets. Please indicate the number of openings per inch, opening size or micron rating of the wire cloth you need, along with the wire diameter(s) you require. Our wire cloth also comes in various weave types, including plain, twill, plain Dutch and twill Dutch.

- Width and Length. Standard widths are 36″, 40″, 48″ and 60″ and a standard roll is 100 feet long, though as a woven product the roll length can vary by plus or minus 10 percent.

- Material. Whether it’s aluminum, brass, copper or stainless steel wire mesh, we can supply cloth from any metal or alloy needed.

In addition to our standard products, we can produce custom weave products in the widths, lengths, types, shapes, sizes, quantities and combinations you need based on your specifications or equipment limitations.

Newark Wire Cloth offers customers a wide selection of:

- Opening sizes

- Widths and lengths

- Materials

- Customized products

Let our experienced sales staff help you select the right Newark Wire Cloth product today.

Newark Wire Cloth is more than just a manufacturer of stainless wire cloth, we are the expert weaver. As ‘the source’, Newark offers a broad range of industrial wire cloth – Space Cloth, Mesh Cloth, and even Micronic Filter Cloth. Many items are considered ‘Stock’ and are ready for immediate shipment. Your choice of wire sizes may range from 1″ diameter down to wire sizes finer than human hair. Mesh opening sizes range from 4″ and larger down to one micron (.00003937 inch). With such wide variation, Newark Wire produces a variety of versatile weaves. The type of weave is frequently dictated by the wire diameter or the opening size desired, or by a combination of these factors, types and materials to suit virtually any requirement. Since stainless wire cloth is produced in such varying combinations of wire diameter and opening size, its use has been widely accepted throughout the industry. It is extremely versatile in application. Whether you’re sizing, separating, sifting, filtering or protecting, industrial wire cloth will do the job.

Newark Wire Cloth is more than just a manufacturer of stainless wire cloth, we are the expert weaver. As ‘the source’, Newark offers a broad range of industrial wire cloth – Space Cloth, Mesh Cloth, and even Micronic Filter Cloth. Many items are considered ‘Stock’ and are ready for immediate shipment. Your choice of wire sizes may range from 1″ diameter down to wire sizes finer than human hair. Mesh opening sizes range from 4″ and larger down to one micron (.00003937 inch). With such wide variation, Newark Wire produces a variety of versatile weaves. The type of weave is frequently dictated by the wire diameter or the opening size desired, or by a combination of these factors, types and materials to suit virtually any requirement. Since stainless wire cloth is produced in such varying combinations of wire diameter and opening size, its use has been widely accepted throughout the industry. It is extremely versatile in application. Whether you’re sizing, separating, sifting, filtering or protecting, industrial wire cloth will do the job.

Wire Cloth is produced as a woven or a welded specification. Welded mesh is only available in a relatively few specification as compared to the woven product. In the manufacturing process each individual wire intersection is resistance spot welded; no filler metal is added.

Wire Cloth is produced as a woven or a welded specification. Welded mesh is only available in a relatively few specification as compared to the woven product. In the manufacturing process each individual wire intersection is resistance spot welded; no filler metal is added.